One Man’s Mission: Rebuilding Costa Rica’s Southern Pacific Coast’s Chocolate Industry

By Gary Garrett

By Gary Garrett

Ahhh, chocolate, the Food of the Gods as it’s Latin name translates. So many varieties,forms and flavors to satisfy our craving. A rich part of Costa Rica’s history. But times have changed and a small group of people are determined to bring back an industry that could once again thrive in Costa Rica.

The Man

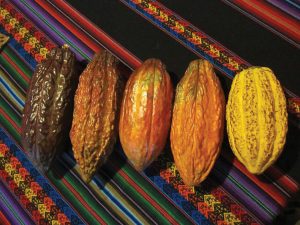

Meet Jay Holecek, certified therapeutic chef and Chocolate Ambassador to our area. His mission is to educate local farmers on how to grow cacao using ecologically sustainable practices and in turn make a decent living for them and their families. He became interested in chocolate after graduating from Bauman College in California, a holistic culinary school that teaches chefs the art of treating immune and digestive disorders through nutrition while pleasing the palate . A friend had a company who produced among other foods, fine-flavor chocolate. Realizing a win-win situation, Jay headed to Costa Rica and started researching how cacao producers could make cacao a profitable crop while maintaining an ecological balance so desperately needed in the rainforest. But competing at the commodity level is nearly impossible as the farmer’s profit is miniscule. 97% of the price of a grocery store candy bar is added through the processing, distribution, packaging, marketing, and profit for the mega chocolate companies like Hershey’s and Mars. So why bother? The key is to compete in the fine-flavor, high end chocolate market where 80% of the production comes from small family-owned farms in the three cacao producing regions of the world (West Africa, Central and South America, Southeast Asia and Micronesia). It takes just the right tropical climate and forest cover to grow high quality,organic cacao trees and in turn, fine-flavor chocolate. Enter Jay and his mission.

Chocolate’s History in Central America

First, however, a little background is helpful on the cacao bean and its relationship to Central America and Costa Rica in particular to understanding Jay’s mission. Originating in the tropical portions of the Americas, cacao was revered by the Aztecs and Mayans just as gold was. For centuries it was traded as currency and when the Spanish settled the area they were intrigued by this fermented bean that was used as a soothing yet bitter drink by the natives. They started adding cane sugar and honey and soon it was exported to Europe where it became a status symbol for royalty and the wealthy. Through time and experimentation, it was processed into solid form and a whole new world of chocolate was born. As these European settlers grew in numbers in Costa Rica, they introduced many other crops from their native lands and eventually the cacao plantations dwindled in size and number. Then in 1979, a fungus blight wiped out 95% of the cacao crop in Costa Rica and coupled with lowering prices on the world commodity market, cacao all but disappeared and was taken over by the vast palm plantations seen today. There are several nearby farms including Finca Kobo in Osa, La Iguana near Parrita, Villa Vanilla in Villa Nuevo, Rio Sierpe Cafe in Palmar Norte, and a major chocolatier, Sibu, near San Jose, helping revive this once thriving crop.

Jay’s Mission and How You Can Help

Through seminars, meetings, and private consultation, Jay’s mission is threefold. First, to educate the owners of small family farms in our area how to grow and sustain high-quality, organic cacao trees, harvest them using ecologically sound practices, and help them build a market for their beans in the US. Secondly, inform consumers on how to process their own chocolate at home, which is a complicated process on a large scale but can be easily done at home with the right education and tools. Thirdly, eventually use the local farmers as a source for his own chocolate making business and in-home customers in the future. Making fine-flavored chocolate is not only about sourcing the right raw beans but using finely-tuned processing techniques as described in the accompanying box. Jay suggests the following to delve deeper into the chocolate world.

- Learn to taste chocolate by taking classes and trying as many different kinds of chocolate to learn what you like the most.

- Visit and experience the forests, farms, and makers to understand first hand what it takes to produce chocolate.

- Support the regeneration of the land and the farmers producing this and other valuable jungle products by sponsoring a tree through Communitycarbontrees.org.

- learn how to make your own chocolate at home from bean to bar by taking my or other chocolate making classes.

Steps in processing chocolate from bean to bar

Fermentation: a volume of beans are collected into piles or bins where the native microbes activate the fermentation of the sugary pulp around the beans. This generates heat, alcohols, acids and microbes that develop the “flavor precursors” that become the unique chocolate flavors later in the process. This alchemical step is the most important for developing the qualities and flavors of chocolate.This step can take anywhere from 3-10 days

Drying: immediately after proper fermentation is complete they are laid out to naturally dry in the sun. This slow drying process allows for further flavor development and the preservation of the beans for storage and transport

Roasting: This is the second most important step in the flavor development of chocolate. Beans are roasted in various systems from baking ovens to coffee roasters to custom designs. This step is normally reserved for the chocolate makers as their expression of the qualities of the beans they are working with.

Cracking/Winnowing: soon after roasting the cooled beans are “cracked” or broken up to help the fibrous and off flavor husks be completely removed during the winnowing step. Winnowing is the separation of the “nibs” and husks by blowing air and screening.

Grinding/Refining: The cleaned nibs are then ground into coarse paste, called “liquor”. Various makers process them uniquely at this stage with different techniques and equipment, but generally its mixed with sugar and other additions and refined down to the very smooth texture of finished chocolate that we all know and love. This is the last step where aeration, heat and particle reduction contributes to the important flavor development unique to chocolate as we know it.

Tempering/Molding: For appearance, stability and handling chocolate is tempered through a heating, cooling and warm hold process that is precisely controlled to form 1 of the most stable of the 5 different fat crystals found in chocolate. Once in temper, chocolate is poured into molds and cooled to set.

You can email Jay to learn more at [email protected] and to discuss how you can help local farmers provide a decent income for their families.